The simplest way of supplying sites with medication is based on a buffer strategy, conventionally configured by trigger and resupply levels that can be adjusted per site. The IRT system generates a shipment request each time one of the pack types at site reaches a low level. It is common to replenish all pack types whenever a shipment request is raised to reduce overall shipment costs and to better maintain the blind within a shipment.

The resupply level should be a function of the recruitment rate, desired resupply frequency, site storage capacity, and study overage. When only using buffer strategy, the stock sent to site should account for new patients, recurring patient visits after randomization, and any unexpected events requiring new medication, such as a damaged pack.

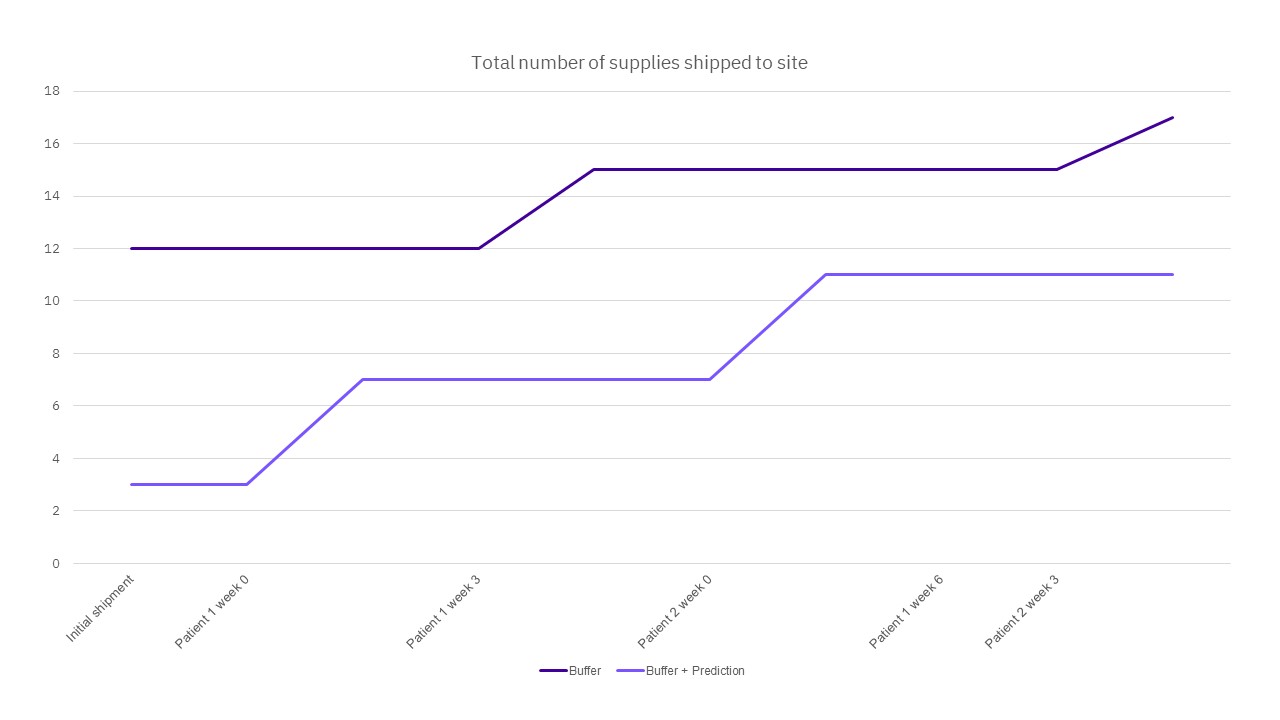

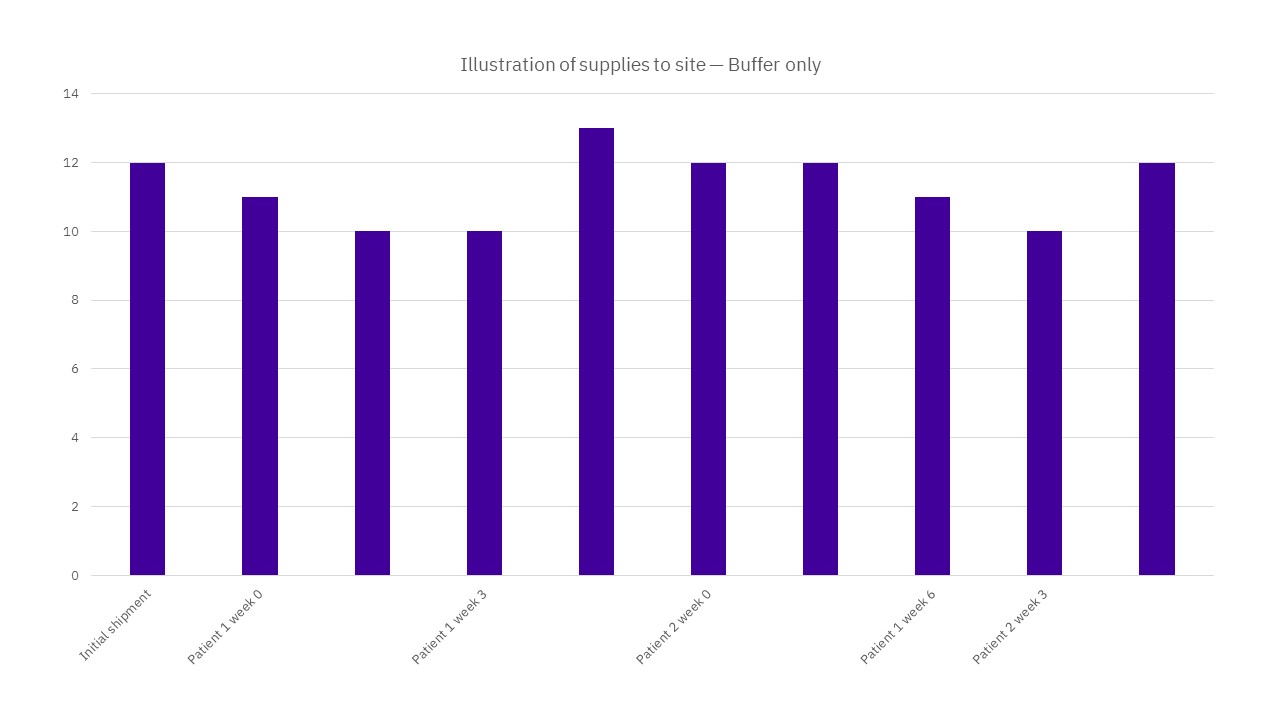

Let’s take the example of an oncology trial, where patients receive 1 pack of trial medication every 3 weeks. For this example, we assume an ideal shipment frequency of every 6 weeks, and that one pack type is required per treatment arm. For a site expecting to recruit one patient per month, a strategy based on buffer stock only would require shipping a minimum of 4 packs per treatment arm. If this trial was to recruit in 3 different treatment arms, it would result in an initial shipment including 12 packs.

This is quite a large amount of medication, which could potentially lead to high level of medication waste at site.

A better way of managing clinical supplies for trials where patients have more than one dispensing visit is by combining the buffer strategy with a prediction algorithm.

Once a subject is randomized into the trial, he or she may require additional medication dispensations, which are usually supplied at further scheduled visits. As this schedule is known by the IRT, the system can calculate which packs are required by the subject and when, which means the needs of a continuing subject can be predicted.

The IRT system looks ahead over a defined time horizon (e.g. 3 weeks) and determines if the current stock on-site is sufficient to supply any visits in this window. If it is not, a new shipment of medication must be sent to supply the unfilled requirements. To reduce the number of shipments to sites, the system looks ahead over a longer time horizon (e.g. 6 weeks) to decide if there are any additional scheduled visits for returning subjects that can be supplied at the same time. The time horizons used are determined based on the desired resupply frequency, site storage, and study overage, alongside other factors such as expected withdrawal rate.

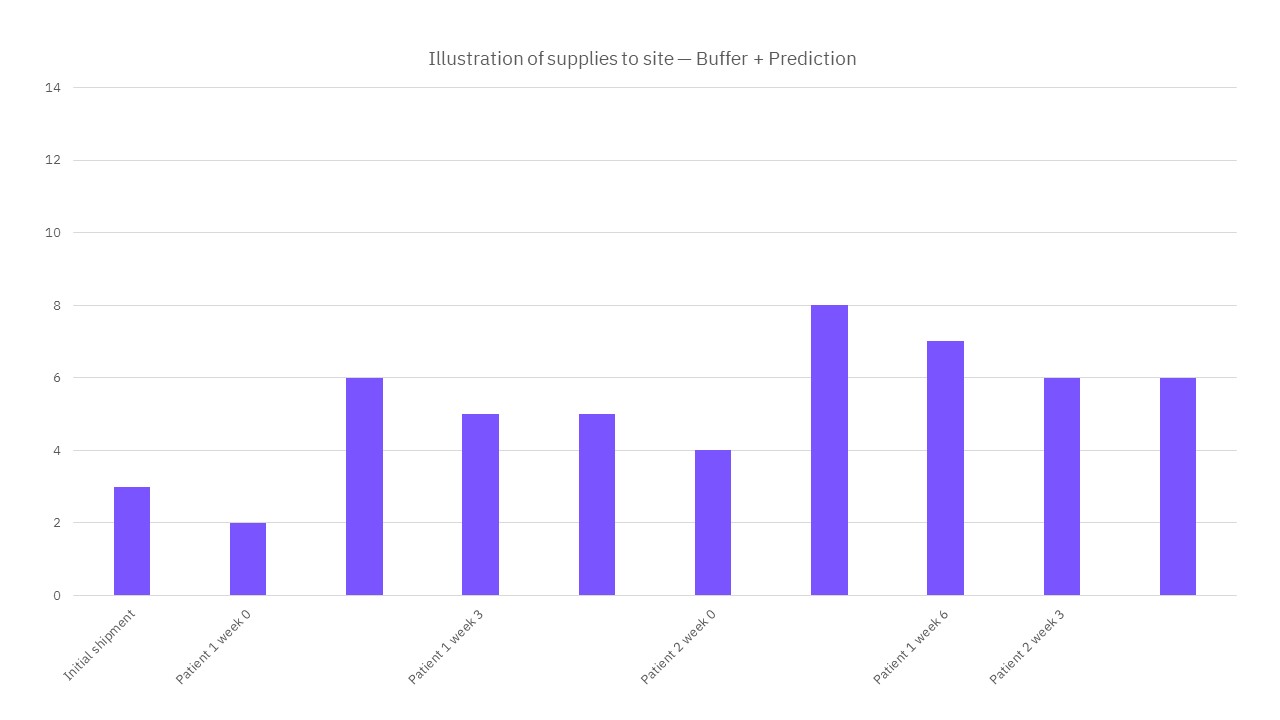

With a combination of buffer strategy and prediction algorithm, the buffer stock at site only needs to cover the first dispensation for each patient (at randomization for example), and unexpected events requiring medication until the next shipment should be raised.

Looking back at our example above, the buffer stock would only include 1 pack per treatment arm, resulting in an initial shipment including 3 packs. The prediction algorithm would cover all dispensing visits after the randomization visit, helping reduce the risk of medication not being available for patient visits.

We recommend using both buffer stock and prediction strategies, to reduce the number of packs shipped to sites initially. In our example, the site has 9 less packs in their initial stock, which reduces medication wasted at site in case recruitment rates are lower than expected. The prediction algorithm helps better control risks related to medication supplies.